Expansion Valves Market: Technology Evolution and Competitive Dynamics (2025–2031)

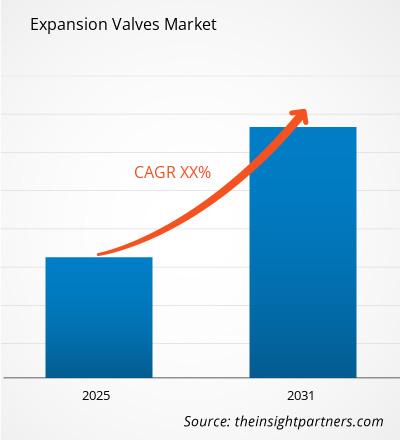

Expansion valves play a critical yet often understated role in HVAC and refrigeration systems. By precisely controlling refrigerant flow, these components directly influence cooling efficiency, system stability, and energy consumption. As global industries emphasize sustainability, automation, and smarter thermal management, the Expansion Valves Market is evolving steadily during the forecast period 2025–2031, supported by innovation and competitive advancements.

Technology Evolution in Expansion Valves

Traditionally, expansion valves were designed for basic pressure and temperature control. Over time, rising performance expectations and stricter energy regulations have driven the development of more advanced valve technologies.

Automatic expansion valves continue to be used in applications with stable operating conditions, particularly in industrial refrigeration. Their mechanical simplicity and durability make them suitable for systems where load variations are minimal.

Thermostatic expansion valves (TXVs) remain the most widely adopted type across commercial and residential HVAC systems. By responding to evaporator outlet temperature, TXVs provide accurate superheat control, improving system efficiency and protecting compressors from damage.

The fastest-growing segment is electronic expansion valves (EEVs). These valves use sensors and electronic controllers to modulate refrigerant flow in real time. EEVs are increasingly integrated into smart HVAC systems, enabling energy optimization, remote monitoring, and compatibility with building management systems.

Despite technological progress, capillary tubes continue to serve cost-sensitive residential applications such as refrigerators and small air conditioners due to their low cost and minimal maintenance. Float valves remain essential in large industrial refrigeration systems, where maintaining correct liquid refrigerant levels is critical for safety and efficiency.

Market Segmentation by Application

The expansion valves market serves a wide range of end-use applications:

Industrial applications include cold storage, food processing, pharmaceuticals, and chemical manufacturing. These environments demand reliable and precise temperature control, driving demand for automatic, float, and increasingly electronic expansion valves.

Automotive applications are gaining importance as vehicle thermal management systems become more complex. Thermostatic and electronic expansion valves are widely used in conventional vehicles and electric vehicles to manage cabin comfort and battery cooling.

Commercial and residential applications represent a major share of market demand. Offices, hospitals, hotels, shopping centers, and residential buildings rely on thermostatic and electronic expansion valves to handle variable cooling loads efficiently.

Competitive Landscape and Key Companies

The expansion valves market is highly competitive, with manufacturers focusing on innovation, product reliability, and global distribution.

EMERSON Climate Technologies is a leading player, offering a broad portfolio of thermostatic and electronic expansion valves integrated with intelligent climate solutions.

Danfoss Industrial Automation is recognized for energy-efficient and digitally controlled expansion valves supporting smart buildings and industrial automation.

Parker Hannifin provides precision-engineered expansion valves designed for high-performance HVAC and automation systems.

CASTEL specializes in refrigeration and air-conditioning valves that meet global quality standards.

Fujikoki America delivers durable expansion valves suited for demanding industrial and commercial environments.

Aashinita Engineering focuses on customized valve solutions tailored to regional and industrial requirements.

Bothra Electric and Refrigeration Company strengthens the market through distribution and aftermarket support.

Armstrong International supports industrial efficiency with precision flow-control technologies.

ACTROL enhances market reach through technical support and strong HVAC distribution networks.

Market Drivers and Outlook (2025–2031)

Key growth drivers include rising demand for energy-efficient HVAC systems, increased adoption of smart and connected technologies, expansion of cold-chain infrastructure, and growth in electric vehicles. While higher upfront costs of electronic expansion valves remain a challenge, long-term energy savings and performance benefits continue to encourage adoption.

Conclusion

The Expansion Valves Market is undergoing a significant transformation as technology advances and competition intensifies. With continued innovation across automatic, thermostatic, electronic, capillary, and float valve technologies, and strong participation from global and regional players, the market is well positioned for sustained growth throughout the 2025–2031 forecast period.

Expansion valves play a critical yet often understated role in HVAC and refrigeration systems. By precisely controlling refrigerant flow, these components directly influence cooling efficiency, system stability, and energy consumption. As global industries emphasize sustainability, automation, and smarter thermal management, the Expansion Valves Market is evolving steadily during the forecast period 2025–2031, supported by innovation and competitive advancements.

Technology Evolution in Expansion Valves

Traditionally, expansion valves were designed for basic pressure and temperature control. Over time, rising performance expectations and stricter energy regulations have driven the development of more advanced valve technologies.

Automatic expansion valves continue to be used in applications with stable operating conditions, particularly in industrial refrigeration. Their mechanical simplicity and durability make them suitable for systems where load variations are minimal.

Thermostatic expansion valves (TXVs) remain the most widely adopted type across commercial and residential HVAC systems. By responding to evaporator outlet temperature, TXVs provide accurate superheat control, improving system efficiency and protecting compressors from damage.

The fastest-growing segment is electronic expansion valves (EEVs). These valves use sensors and electronic controllers to modulate refrigerant flow in real time. EEVs are increasingly integrated into smart HVAC systems, enabling energy optimization, remote monitoring, and compatibility with building management systems.

Despite technological progress, capillary tubes continue to serve cost-sensitive residential applications such as refrigerators and small air conditioners due to their low cost and minimal maintenance. Float valves remain essential in large industrial refrigeration systems, where maintaining correct liquid refrigerant levels is critical for safety and efficiency.

Market Segmentation by Application

The expansion valves market serves a wide range of end-use applications:

Industrial applications include cold storage, food processing, pharmaceuticals, and chemical manufacturing. These environments demand reliable and precise temperature control, driving demand for automatic, float, and increasingly electronic expansion valves.

Automotive applications are gaining importance as vehicle thermal management systems become more complex. Thermostatic and electronic expansion valves are widely used in conventional vehicles and electric vehicles to manage cabin comfort and battery cooling.

Commercial and residential applications represent a major share of market demand. Offices, hospitals, hotels, shopping centers, and residential buildings rely on thermostatic and electronic expansion valves to handle variable cooling loads efficiently.

Competitive Landscape and Key Companies

The expansion valves market is highly competitive, with manufacturers focusing on innovation, product reliability, and global distribution.

EMERSON Climate Technologies is a leading player, offering a broad portfolio of thermostatic and electronic expansion valves integrated with intelligent climate solutions.

Danfoss Industrial Automation is recognized for energy-efficient and digitally controlled expansion valves supporting smart buildings and industrial automation.

Parker Hannifin provides precision-engineered expansion valves designed for high-performance HVAC and automation systems.

CASTEL specializes in refrigeration and air-conditioning valves that meet global quality standards.

Fujikoki America delivers durable expansion valves suited for demanding industrial and commercial environments.

Aashinita Engineering focuses on customized valve solutions tailored to regional and industrial requirements.

Bothra Electric and Refrigeration Company strengthens the market through distribution and aftermarket support.

Armstrong International supports industrial efficiency with precision flow-control technologies.

ACTROL enhances market reach through technical support and strong HVAC distribution networks.

Market Drivers and Outlook (2025–2031)

Key growth drivers include rising demand for energy-efficient HVAC systems, increased adoption of smart and connected technologies, expansion of cold-chain infrastructure, and growth in electric vehicles. While higher upfront costs of electronic expansion valves remain a challenge, long-term energy savings and performance benefits continue to encourage adoption.

Conclusion

The Expansion Valves Market is undergoing a significant transformation as technology advances and competition intensifies. With continued innovation across automatic, thermostatic, electronic, capillary, and float valve technologies, and strong participation from global and regional players, the market is well positioned for sustained growth throughout the 2025–2031 forecast period.

Expansion Valves Market: Technology Evolution and Competitive Dynamics (2025–2031)

Expansion valves play a critical yet often understated role in HVAC and refrigeration systems. By precisely controlling refrigerant flow, these components directly influence cooling efficiency, system stability, and energy consumption. As global industries emphasize sustainability, automation, and smarter thermal management, the Expansion Valves Market is evolving steadily during the forecast period 2025–2031, supported by innovation and competitive advancements.

Technology Evolution in Expansion Valves

Traditionally, expansion valves were designed for basic pressure and temperature control. Over time, rising performance expectations and stricter energy regulations have driven the development of more advanced valve technologies.

Automatic expansion valves continue to be used in applications with stable operating conditions, particularly in industrial refrigeration. Their mechanical simplicity and durability make them suitable for systems where load variations are minimal.

Thermostatic expansion valves (TXVs) remain the most widely adopted type across commercial and residential HVAC systems. By responding to evaporator outlet temperature, TXVs provide accurate superheat control, improving system efficiency and protecting compressors from damage.

The fastest-growing segment is electronic expansion valves (EEVs). These valves use sensors and electronic controllers to modulate refrigerant flow in real time. EEVs are increasingly integrated into smart HVAC systems, enabling energy optimization, remote monitoring, and compatibility with building management systems.

Despite technological progress, capillary tubes continue to serve cost-sensitive residential applications such as refrigerators and small air conditioners due to their low cost and minimal maintenance. Float valves remain essential in large industrial refrigeration systems, where maintaining correct liquid refrigerant levels is critical for safety and efficiency.

Market Segmentation by Application

The expansion valves market serves a wide range of end-use applications:

Industrial applications include cold storage, food processing, pharmaceuticals, and chemical manufacturing. These environments demand reliable and precise temperature control, driving demand for automatic, float, and increasingly electronic expansion valves.

Automotive applications are gaining importance as vehicle thermal management systems become more complex. Thermostatic and electronic expansion valves are widely used in conventional vehicles and electric vehicles to manage cabin comfort and battery cooling.

Commercial and residential applications represent a major share of market demand. Offices, hospitals, hotels, shopping centers, and residential buildings rely on thermostatic and electronic expansion valves to handle variable cooling loads efficiently.

Competitive Landscape and Key Companies

The expansion valves market is highly competitive, with manufacturers focusing on innovation, product reliability, and global distribution.

EMERSON Climate Technologies is a leading player, offering a broad portfolio of thermostatic and electronic expansion valves integrated with intelligent climate solutions.

Danfoss Industrial Automation is recognized for energy-efficient and digitally controlled expansion valves supporting smart buildings and industrial automation.

Parker Hannifin provides precision-engineered expansion valves designed for high-performance HVAC and automation systems.

CASTEL specializes in refrigeration and air-conditioning valves that meet global quality standards.

Fujikoki America delivers durable expansion valves suited for demanding industrial and commercial environments.

Aashinita Engineering focuses on customized valve solutions tailored to regional and industrial requirements.

Bothra Electric and Refrigeration Company strengthens the market through distribution and aftermarket support.

Armstrong International supports industrial efficiency with precision flow-control technologies.

ACTROL enhances market reach through technical support and strong HVAC distribution networks.

Market Drivers and Outlook (2025–2031)

Key growth drivers include rising demand for energy-efficient HVAC systems, increased adoption of smart and connected technologies, expansion of cold-chain infrastructure, and growth in electric vehicles. While higher upfront costs of electronic expansion valves remain a challenge, long-term energy savings and performance benefits continue to encourage adoption.

Conclusion

The Expansion Valves Market is undergoing a significant transformation as technology advances and competition intensifies. With continued innovation across automatic, thermostatic, electronic, capillary, and float valve technologies, and strong participation from global and regional players, the market is well positioned for sustained growth throughout the 2025–2031 forecast period.

0 Comments

0 Shares

475 Views